How quickly can you fix things?

Inventing things can also mean fixing things.

What's the first thing you do when something breaks?

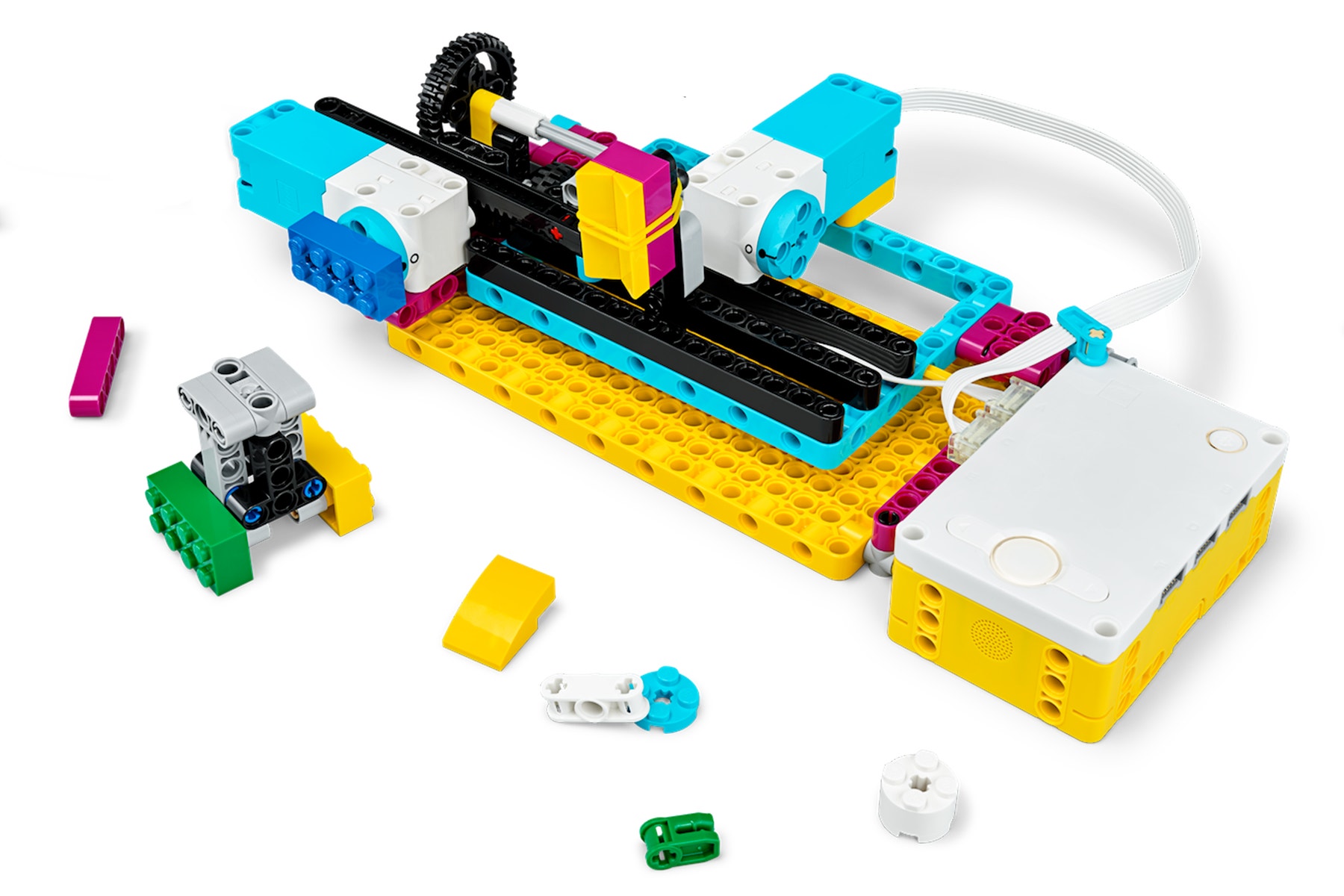

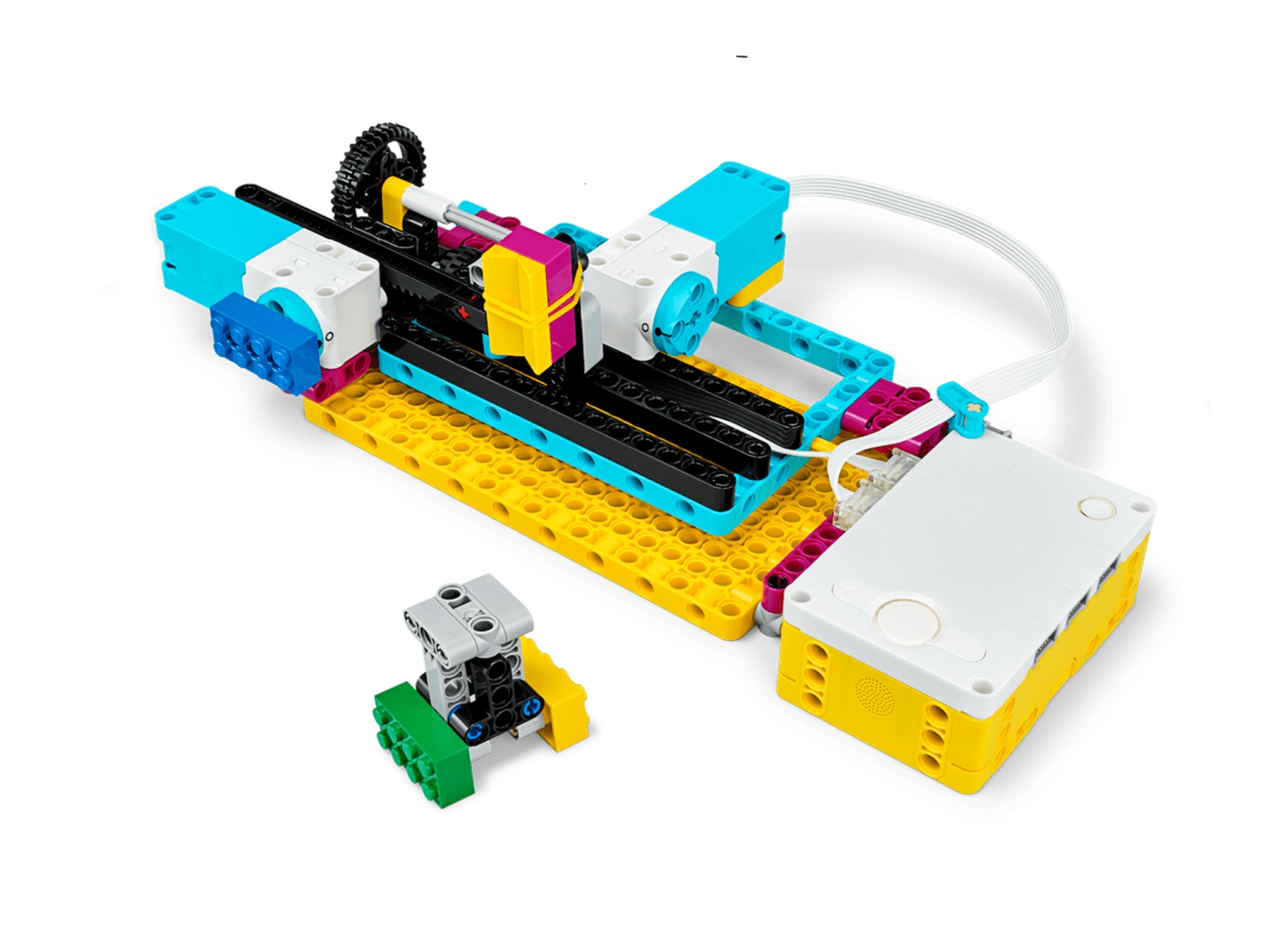

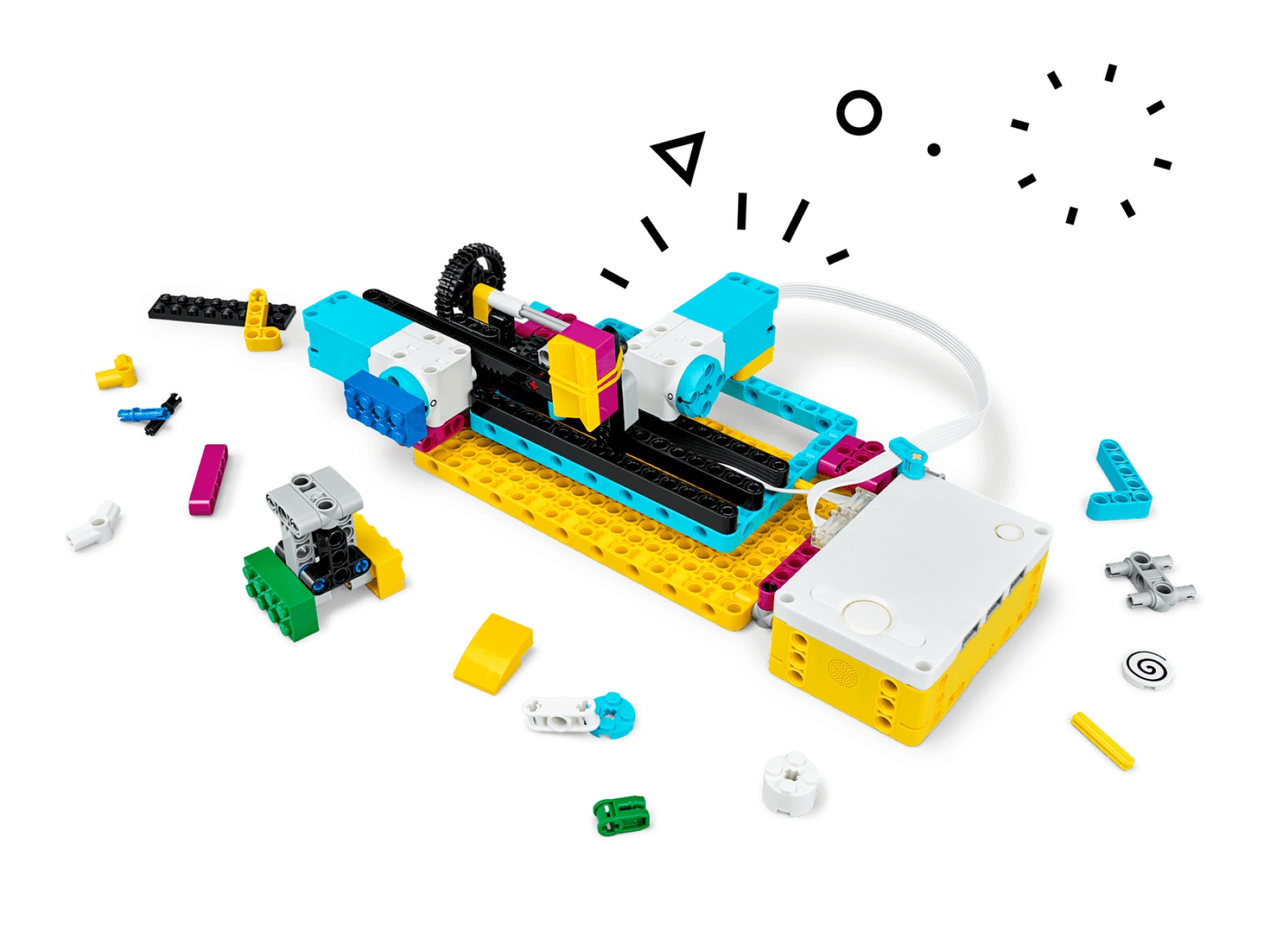

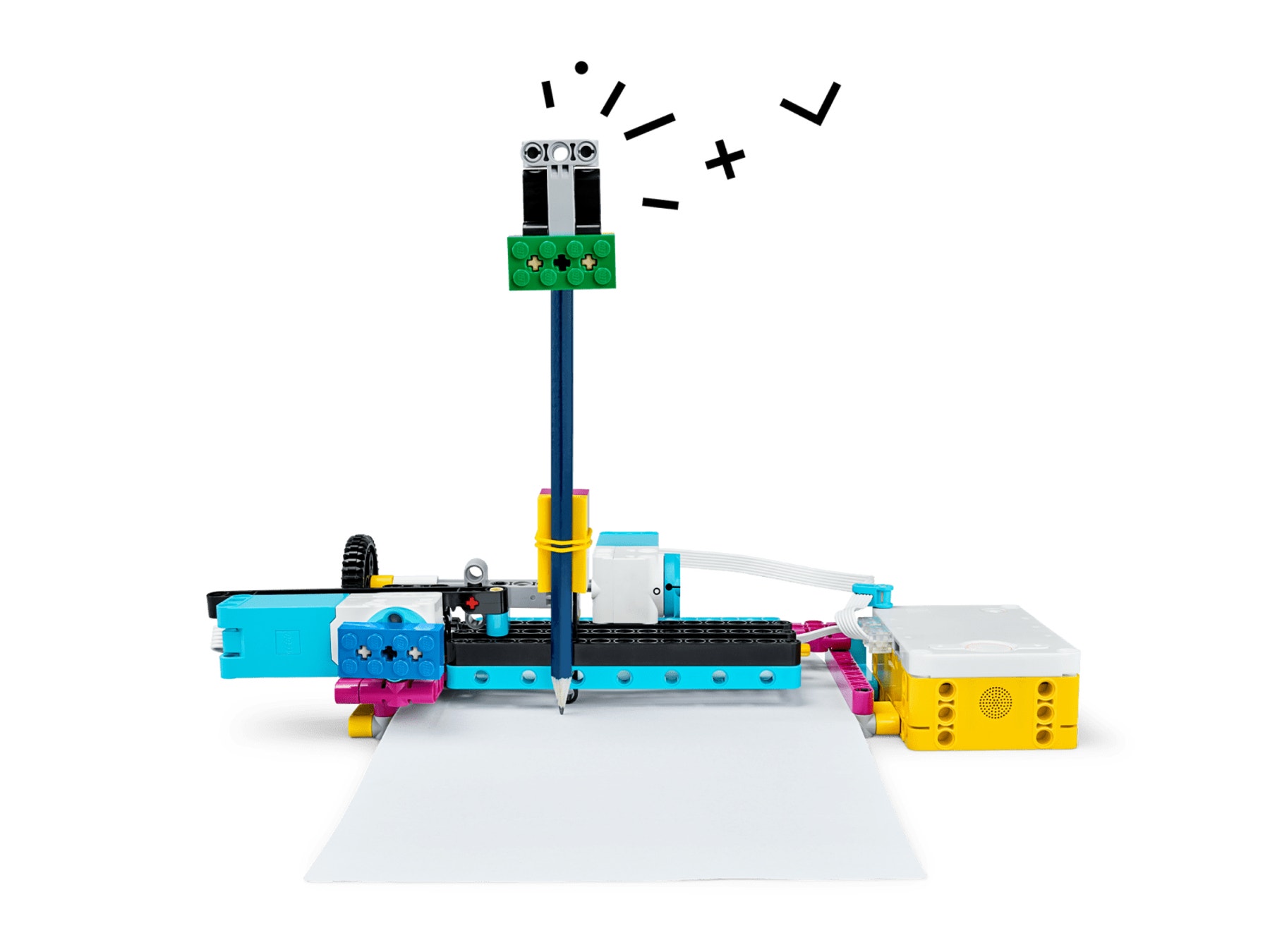

This CNC needs to be fixed.

You must troubleshoot and fix your CNC! Start by building the machine:

- CNC Top

- CNC Bottom

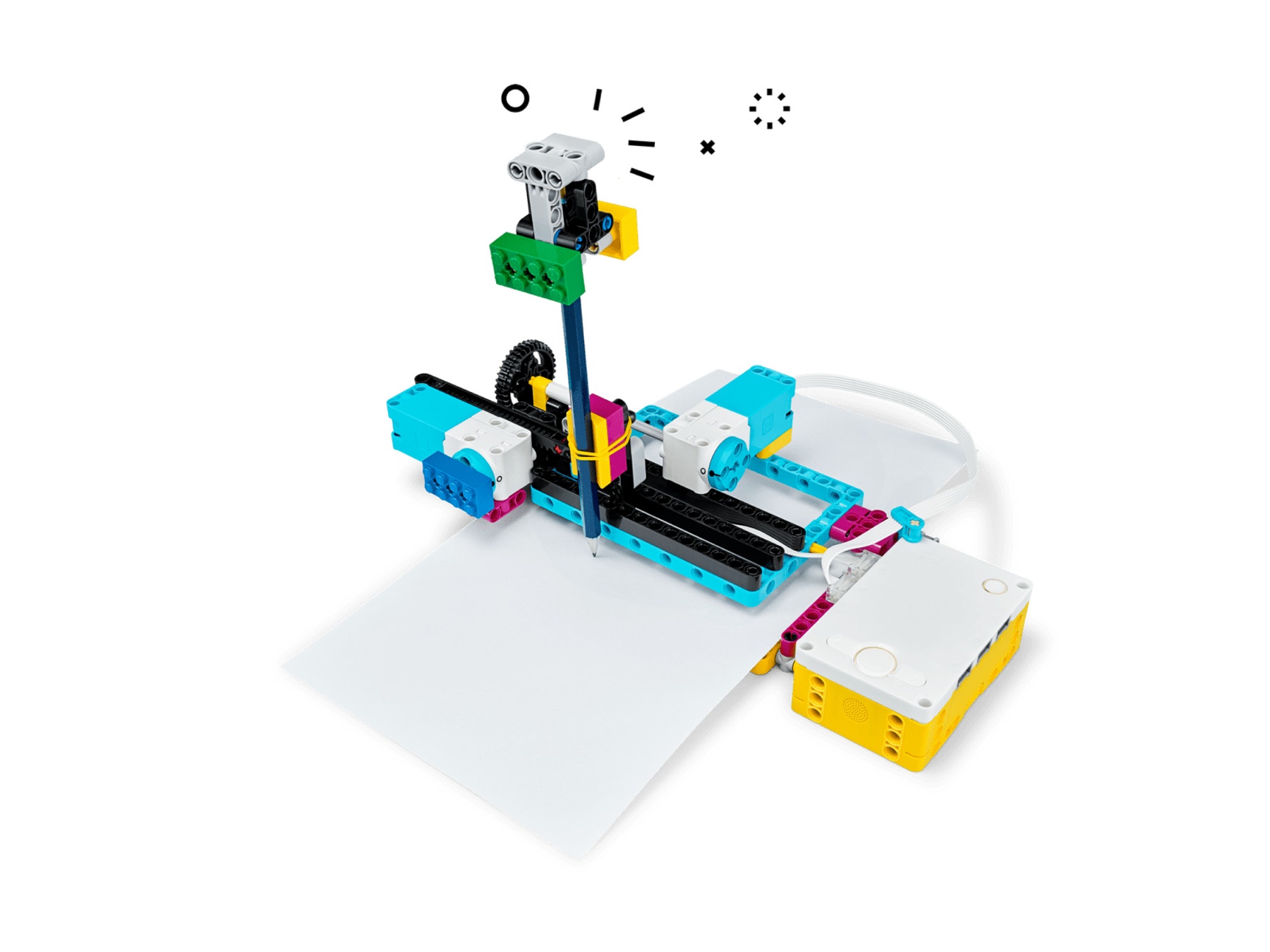

Play This Program to Activate Your CNC

What goes wrong?

Describe what you see. Look for the problem.

The CNC is supposed to help you cut parts, but something isn't right.

Don’t change the program. The issues will be found on the CNC itself.

Have you figured out what’s wrong?

- Find out why the CNC isn’t working as it should.

- Fix the issues.

- Take a picture or video of the issues you’ve found and document your fixes.

Time for an upgrade!

Now that your CNC is fixed, make at least 2 improvements. You could:

- Create a reset motor position stack.

- Use the Color Sensor and a black line to create an automatic paper feeder.

- Create a troubleshooting guide.

- Come up with your own upgrade!

Evaluate your performance.

Think about what you did well and how you could improve for next time.

Fixing things makes them last longer. It’s awesome that you can fix stuff!