Stamping Press

Investigate how to make an energy efficient stamping press.

Connect

(5-10 Minutes)

A stamping press stamps or presses a material into a new shape or size. To be as efficient as possible, the process needs to use the least amount of energy possible, yet work as fast as possible.

Build the Stamping Press and investigate how energy efficient it is. Let’s find out!

Construct

(20-25 Minutes)

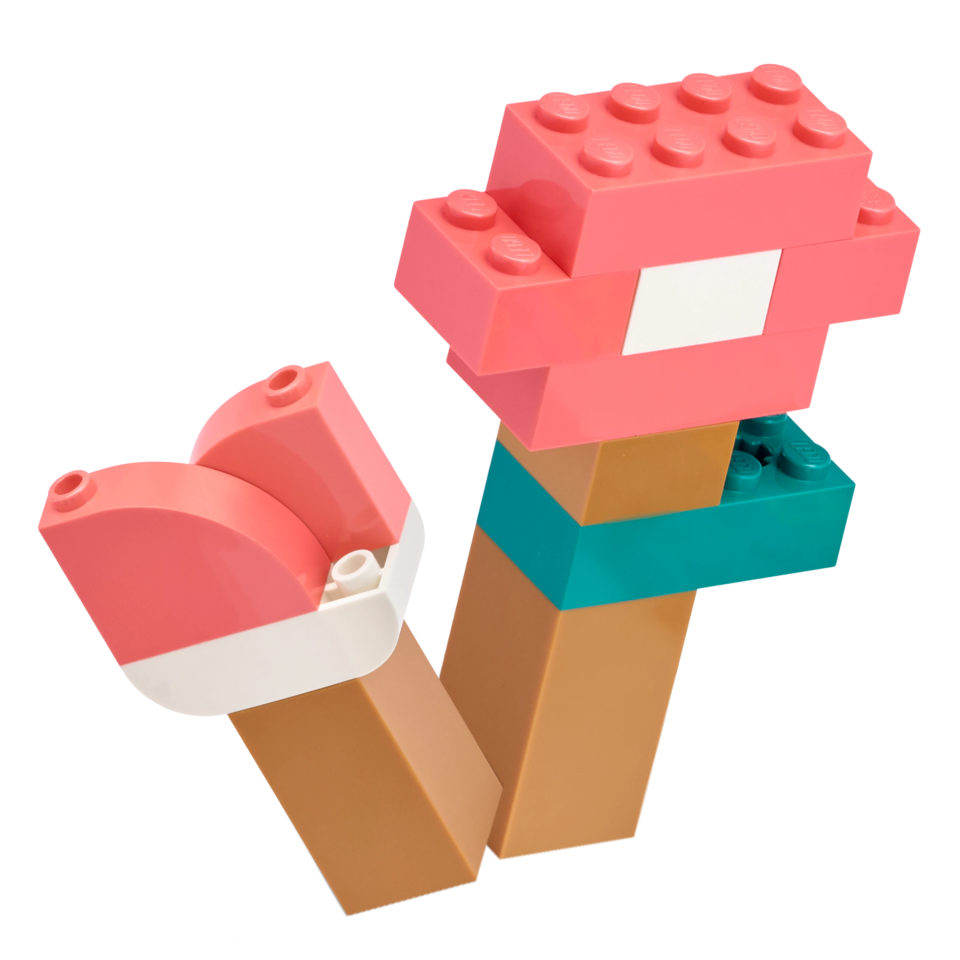

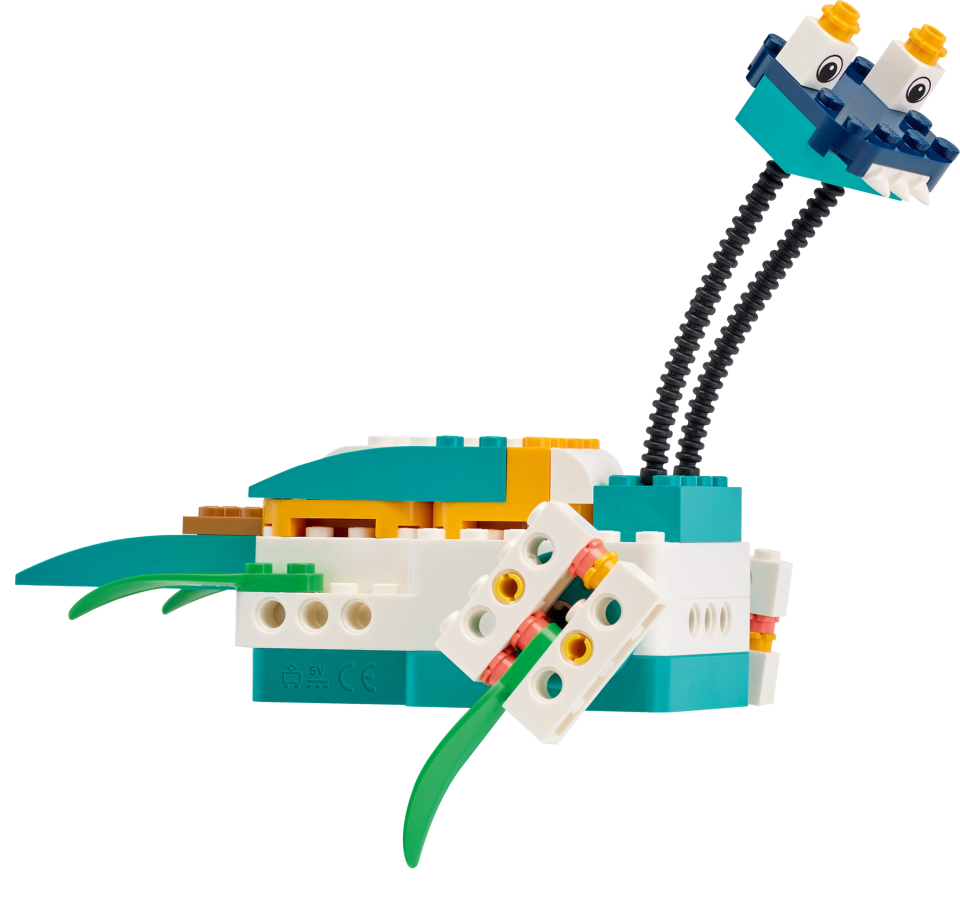

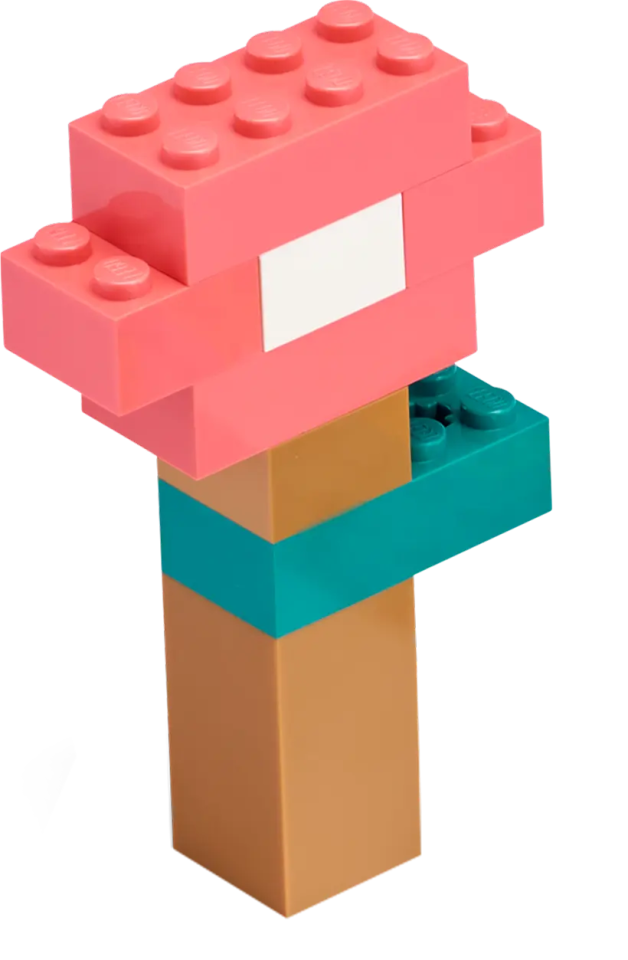

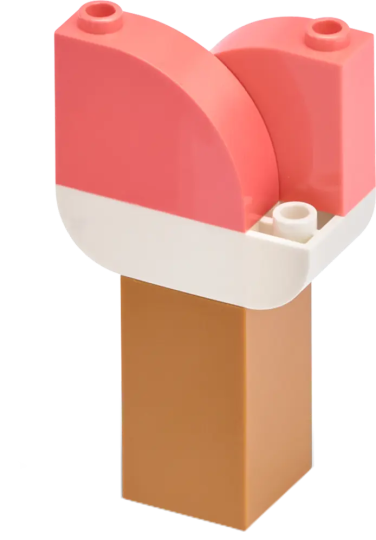

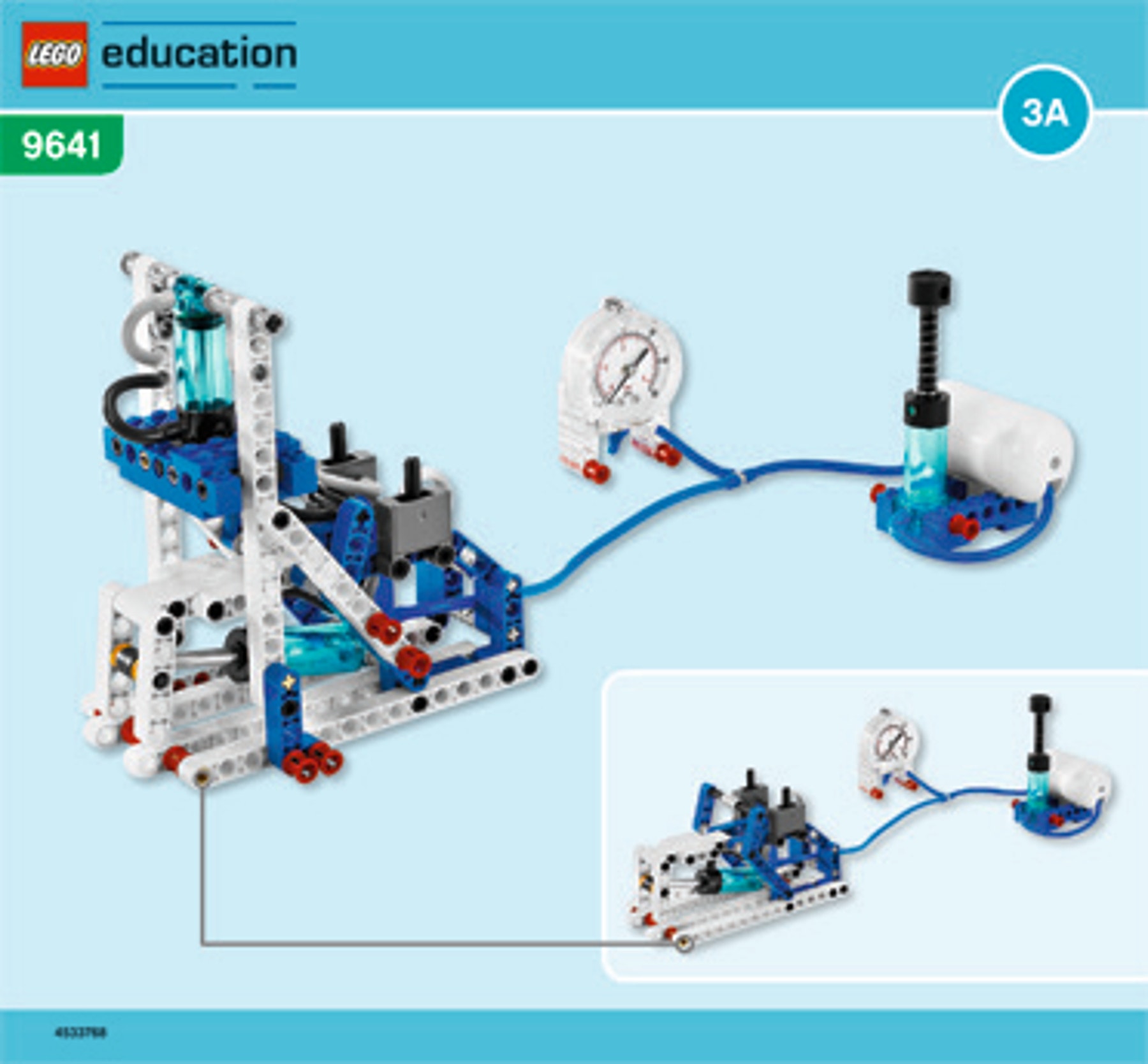

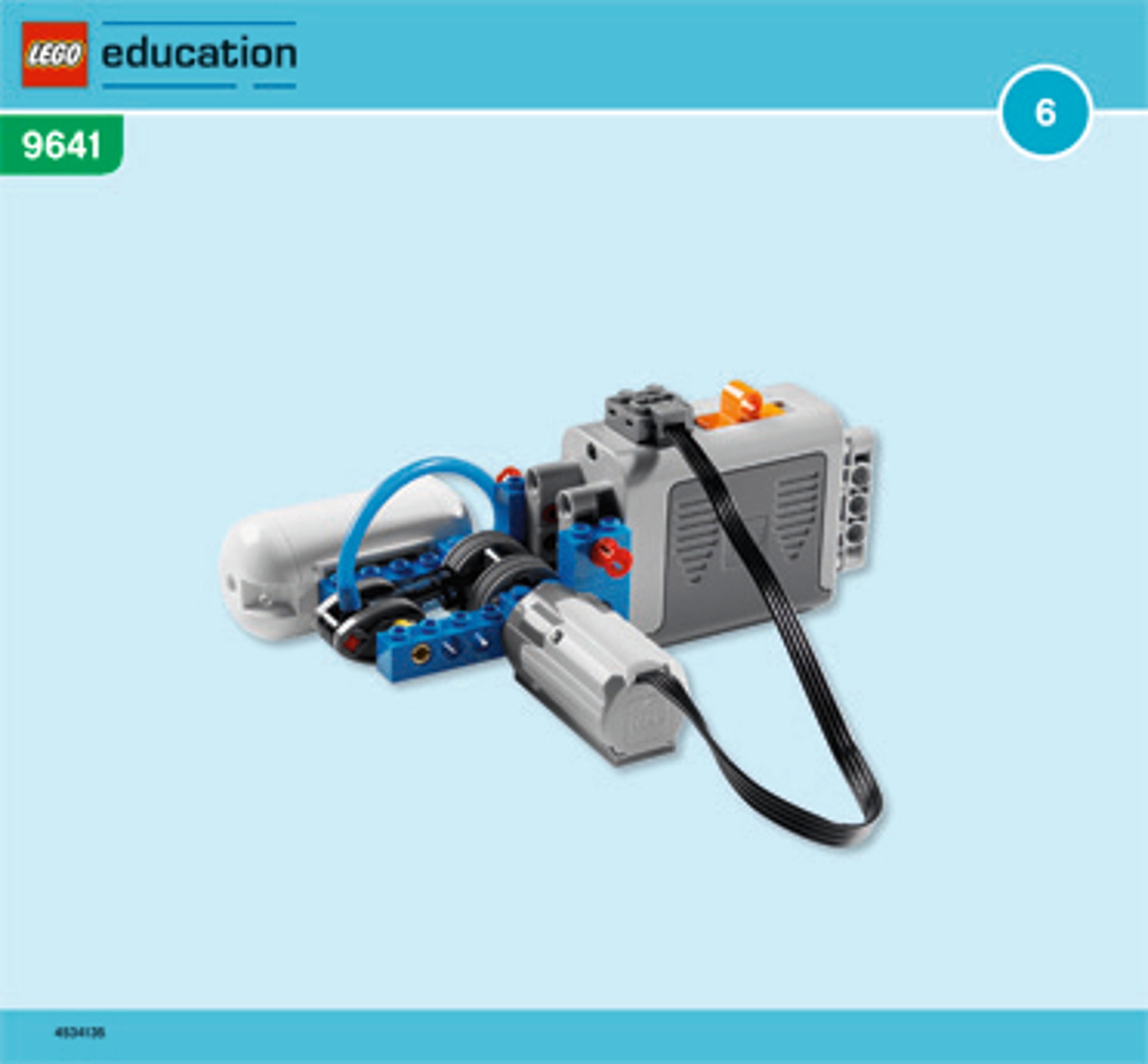

Build the Stamping Press

(All of book 3A and book 3B to page 14, step 12).

Pump air into the system and use the manometer to detect whether there is an air leak.

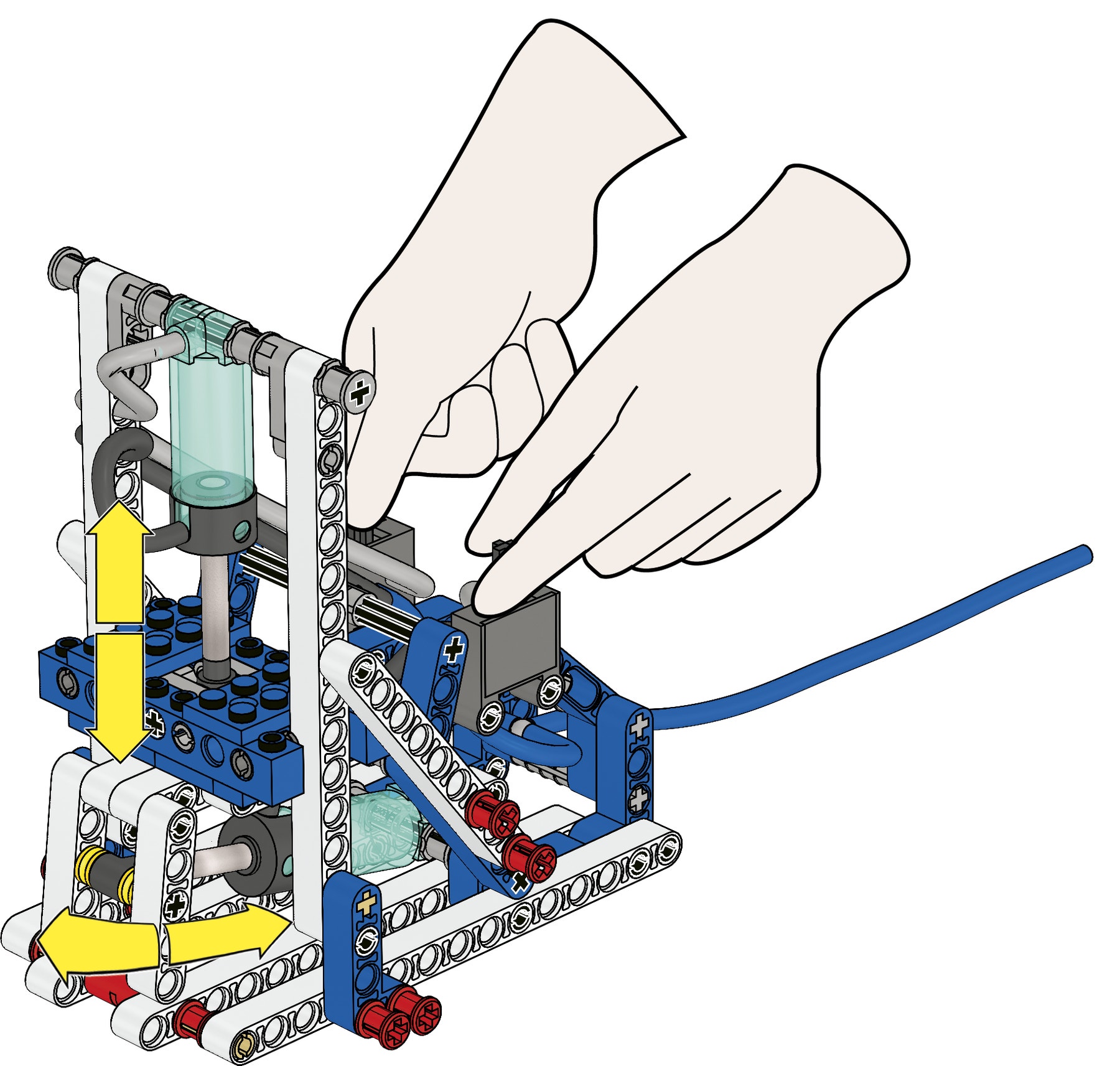

Try all valve settings and test if the Stamping Press can do all four possible strokes; press down, press up, ejector down, and ejector up. Make sure all moving parts move freely.

Then move the press up, the ejector forward and empty the air tank.

Hint

The easiest way to empty the air tank is to disconnect the tube going from the air tank to the valve.

Contemplate

(20-25 minutes)

How energy efficient is your press?

One complete work cycle is four ‘strokes’ in sequence; press down, press up, ejector down, and ejector up. Find out how repeated work cycles affect loss of pressure.

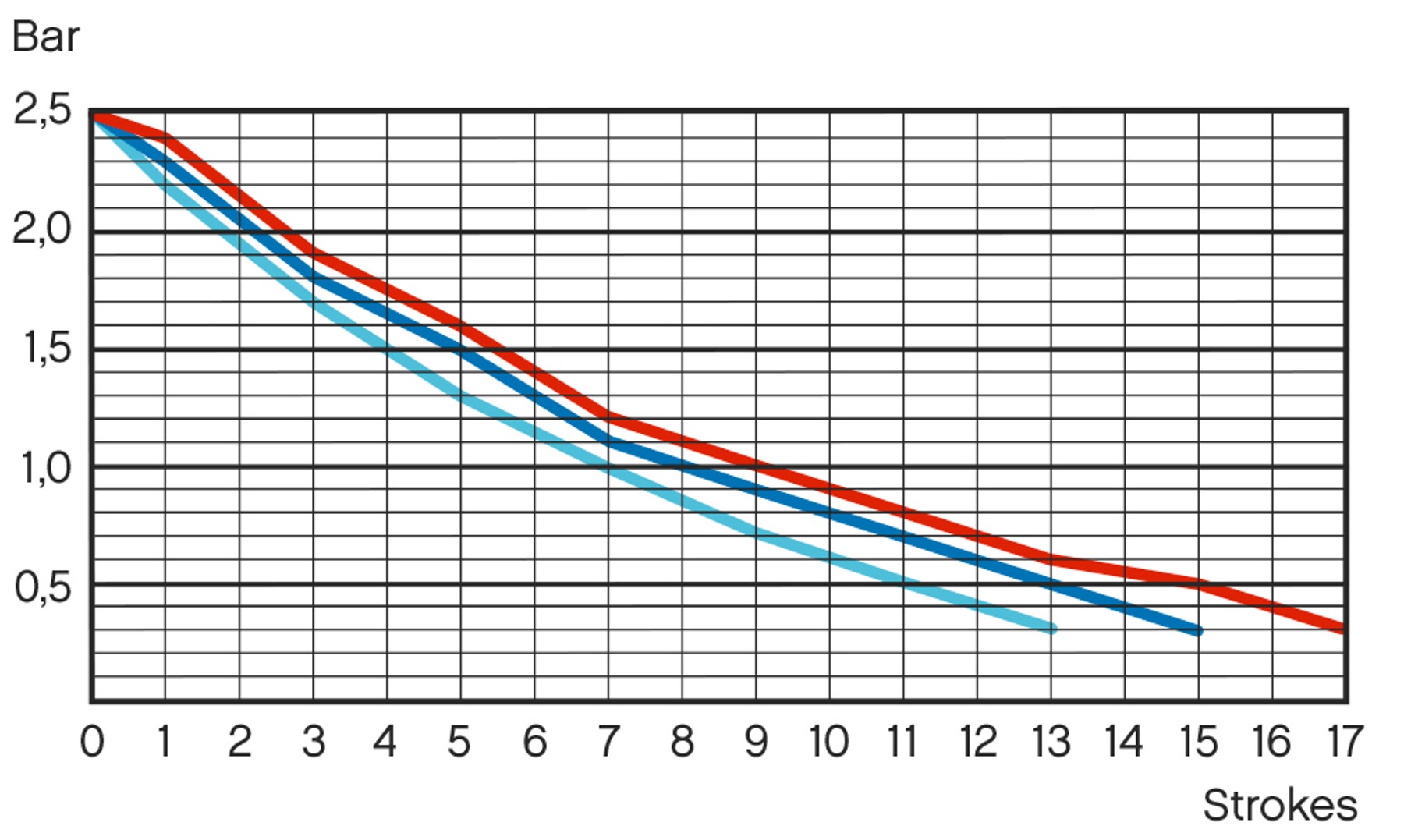

First, predict how repeated work cycles affect the loss of pressure when working with empty Stamping Press A. Record your predictions on the graph paper as a dotted line starting at 2.5 bars and ending near zero bar. Remember it doesn’t have to be a straight line.

Then, test how Stamping Press A’s repeated work cycles actually affect the loss of pressure. Start with 2.5 bars of pressure. Record your findings on the graph paper.

Next, follow the same procedure for Stamping Presses B and C.

Test several times to make sure your results are consistent.

Hint

For a more accurate graph, record your findings after each stroke.

Have the students reflect on their investigations by asking questions such as:

• What did you predict would happen and why?

• How does the Stamping Press work, and which type of lever is used?

The stamper delivers a direct press and the ejector uses a complex second class lever.

• How many complete work cycles can you do when starting with 2.5 bars of pressure?

About three complete work cycles.

Continue

(25-30 Minutes)

How good of a press operator are you?

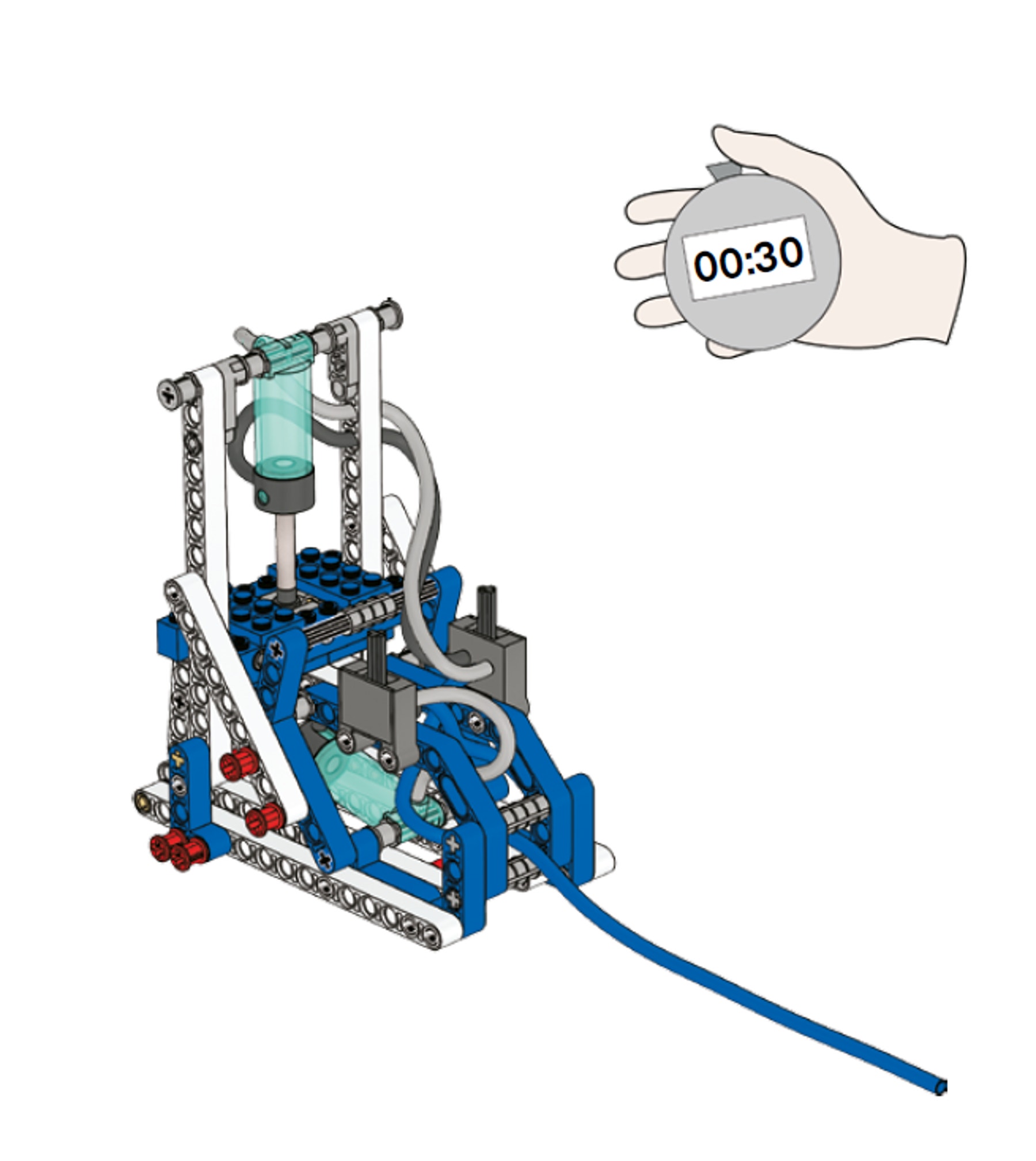

The faster you can operate the empty Stamping Press, the more cost efficient it will be. Find out how many complete work cycles you can finish in 30 seconds.

First, predict how many complete work cycles you can finish in 30 seconds when using an empty Stamping Press. Record your predictions on the worksheet.

Then, test how many complete work cycles you actually finished. Record your findings on the worksheet.

Next, try pressing different objects of your choice and compare the number of complete work cycles you are able to finish.

Hint

Before you start, it is a good idea to decide if you are starting with an empty or full air tank.

Hint

To help overcome the loss of pressure you could build a compressor.

Teacher Support

Students will explore the concepts of:

Area

Behavior of gases under pressure

Forces

Scientific investigation

Assembling components

Control of mechanisms

Evaluating

Properties of materials

Using mechanisms - levers

9686 Simple & Powered Machines Set (two students per set recommended)

9641 Pneumatics Add-on Set

Aluminium foil or cling film

Clay or small pieces of polystyrene foam

Graph paper

Stopwatch or timer

NGSS

Crosscutting Concepts

Cause and effect: Mechanism and explanation

Systems and system models

Structure and Function

Stability and change

Science and Engineering Practices

Ask questions and Defining Problems

Developing and using models

Planning and carrying out investigations

Analyzing and interpreting data

Constructing explanations and designing solutions

Obtaining, evaluating, and communicating information

Common Core Mathematics Standards

MP4 / MP5 / 7.RP.A

Common Core English Language Arts Standards

SL 6-8.1 / RST 6-8.3 / RST 6-8.4 / RST 6-8.7 / WHST 6-8.1 / WHST 6-8.2 / WHST 6-8.4 / WHST 6-8.7

Student Material

Share with:

Google Classroom

Google Classroom